Understanding Electromagnetic Shielding Materials

In an era where electronic devices are ubiquitous, the need for effective electromagnetic shielding materials has become paramount. These materials inhibit electromagnetic interference (EMI), which can disrupt the proper functioning of electronic devices by preventing unwanted electromagnetic radiation from entering or exiting an electronic environment. Understanding the fundamentals of electromagnetic shielding is essential for professionals in electronics, telecommunications, medical technology, and many other fields.

What Are Electromagnetic Shielding Materials?

Electromagnetic shielding materials are substances that block or reduce electromagnetic fields. They are typically conductive or magnetic materials that prevent electromagnetic waves from penetrating or emitting through them, thereby providing a controlled electromagnetic environment. Common types include metals, composites, and conductive polymers, each possessing unique properties that render them suitable for various applications.

Importance of Electromagnetic Shielding

The importance of electromagnetic shielding cannot be overstated. As technological advancements lead to denser circuit designs, the potential for electromagnetic interference grows, posing risks like data loss, equipment malfunction, and increased emissions. Electromagnetic shielding protects sensitive equipment, enhances reliability, and ensures compliance with regulatory standards. Its significance spans diverse fields such as telecommunications, automotive, aerospace, and health technology.

Common Applications in Industry

Electromagnetic shielding is critical across numerous industries. In the telecommunications sector, it safeguards sensitive communication gear from interference. In the medical field, equipment like MRI machines employs shielding to prevent various forms of interference that could distort imaging results. The automotive industry uses shielding materials in electronic systems to prevent disturbances that could affect vehicle reliability. Furthermore, military applications utilize advanced shielding to protect sensitive equipment from external threats.

Types of Electromagnetic Shielding Materials

Metal Shielding Options

Metal remains one of the most popular choices for electromagnetic shielding due to its conductive properties. Common metals used include:

- Copper: Known for its excellent conductivity, copper is often favored for its effectiveness in attenuating both magnetic and electrical waves. Its use is widespread in high-performance shielding applications.

- Aluminum: This lightweight metal offers good conductivity at a lower cost than copper, making it a popular choice for various applications.

- Steel: Often used in industrial applications due to its strength, steel can be particularly effective when plated with other metals like nickel or tin.

- Brass and Nickel: Both metals provide good shielding effectiveness and can be utilized in specific applications where their unique properties are beneficial.

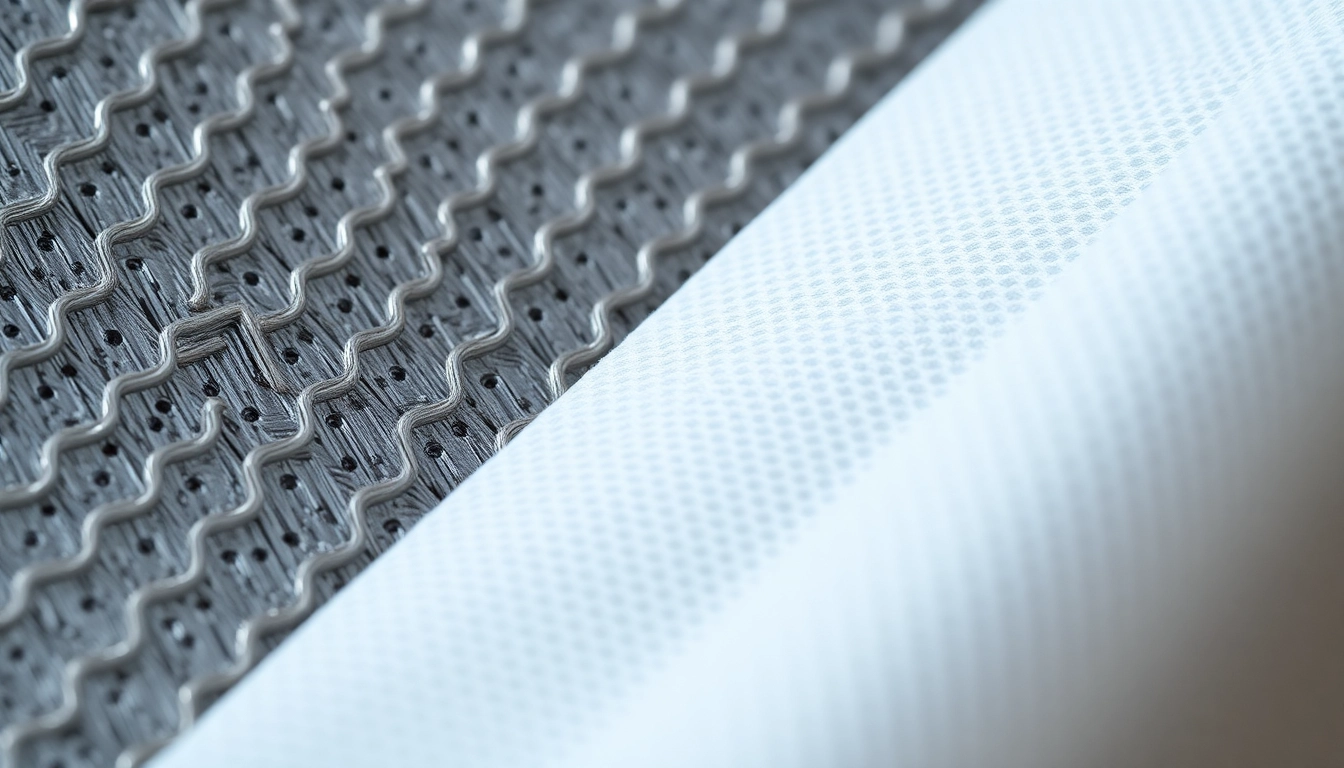

Composite and Flexible Shielding Materials

Composite materials combine two or more distinct materials to enhance shielding effectiveness while maintaining flexibility and lightweight properties. These are particularly useful in applications where rigid shielding cannot be utilized:

- Metal Foams: These materials offer a unique combination of lightweight and mechanical properties while maintaining excellent shielding capabilities.

- Conductive Fabrics: Often used in garments and bags, these materials provide EMI protection in a flexible format, making them ideal for portable devices.

- Metalized Plastics: These materials involve coating plastic substrates with metal layers, providing a balance of protection and weight savings for electronic devices.

Conductive Polymers and Their Uses

Conductive polymers are innovative materials that combine the properties of plastics and metals. They are particularly useful in areas requiring lightweight and flexible options:

- Applications in Electronics: Conductive polymers are utilized in printed circuit boards (PCBs) and electronic enclosures to provide effective shielding without adding bulk.

- Environmental Resistance: These shield materials also offer resistance against moisture and chemicals, which makes them suitable for harsh industrial environments.

Choosing the Right Electromagnetic Shielding Materials

Factors to Consider When Selecting Shielding Materials

Choosing the right electromagnetic shielding materials requires careful evaluation of several factors:

- Conductivity: The ability of the material to conduct electricity and attenuate electromagnetic waves is a primary consideration.

- Weight: For portable equipment, lightweight materials are crucial for maintaining usability without compromising effectiveness.

- Cost: Costs can vary significantly among materials, so determining budget constraints is important for projects.

- Environmental Factors: Resistance to environmental conditions, such as humidity and temperature, can also influence material selection.

Cost vs. Performance Analysis

Several materials can provide excellent performance; however, their costs can vary significantly. Metals like copper perform exceptionally well but come at a higher price. On the other hand, materials like aluminum may offer a more cost-effective solution, albeit with slightly reduced performance. A thorough cost-benefit analysis should be conducted, taking into consideration the specific requirements of the application, including expected performance, longevity, and the environment in which the shielding will operate.

Real-World Case Studies and Applications

Numerous case studies highlight the practical applications of various electromagnetic shielding materials:

- Telecommunications Infrastructure: A company integrated copper-based shielding materials into network components, resulting in a 40% decrease in signal interference, ensuring clearer communication lines.

- Medical Imaging: Hospitals utilizing nickel-coated aluminum shielding in MRI rooms report significant reductions in noise and distortion, allowing for improved diagnostic outcomes.

Testing and Measuring Shielding Effectiveness

Common Testing Methods

To ensure that electromagnetic shielding materials are performing as expected, various testing methods can be employed:

- Shielding Effectiveness Testing: Commonly conducted using specific frequency generators and antennas to assess how much electromagnetic energy passes through a material.

- Field Measurement Techniques: Utilizes complex field strength measurement tools to evaluate real-time environmental shielding effectiveness.

Interpreting Shielding Effectiveness Results

Results from shielding tests must be carefully analyzed to inform design decisions:

- Decibel Measurement: Often, shielding effectiveness is measured in decibels (dB), indicating the reduction of electromagnetic interference.

- Frequency Considerations: Different materials may perform better at specific frequencies; understanding frequency response is crucial for optimal shielding design.

Quality Standards for Shielding Materials

Establishing quality standards is vital for ensuring the reliability and effectiveness of electromagnetic shielding materials:

- Industry Regulations: Adherence to industry standards such as the IEC, AS/NZS, and MIL standards can provide assurance of material effectiveness and safety.

- Material Certification: Certifications from recognized laboratories can also provide additional credibility to the product.

Future Trends in Electromagnetic Shielding Materials

Innovations in Shielding Technologies

Emerging technologies continue to shape the future landscape of electromagnetic shielding materials:

- Nano-Enhanced Materials: Researchers are exploring nano-composites that promise improved shielding with reduced weight and increased flexibility.

- Smart Shielding Solutions: Integration of sensors within shielding materials to monitor environmental conditions and adjust performance dynamically is an exciting frontier.

Environmental Impact and Sustainability Considerations

As industries become more environmentally conscious, the development of sustainable materials for electromagnetic shielding is gaining momentum. Biodegradable polymers and recycled metals are being researched as potential alternatives to conventional shielding materials.

Predictions for the Next Decade

As demand for connected devices grows, so too will the need for effective shielding solutions. We can anticipate:

- Further advancements in composite materials that combine lightweight properties with excellent shielding capabilities.

- Increased focus on regulatory compliance and sustainability standards in material selection processes.